Packaging automation impact in numbers:

- Up to 2.5X increase in productivity

-

12% savings in linear feet per order

Transitioning from a manual process to automated packaging gave Metro Supply Chain the flexibility to scale in its everyday operations and peak seasons, without adding strain to their team.

Save for later

Overview

At Metro Supply Chain, we continually refine our operations to enhance speed, accuracy and sustainability. As part of our commitment to operational excellence and environmental responsibility, we are investing in intelligent automation that strengthens our current performance while positioning our clients for long-term success.

The opportunity for enhancement

With rising demand for increased order-processing capacity and waste reduction, supply chains across the industry are evolving quickly. To maintain our competitive edge, Metro Supply Chain set out to enhance our robust operations by:

- Increasing our pack-out throughput (the number of orders we process)

- Maximizing the use of available warehouse space

- Minimizing our impact on the environment even further

These objectives led us to seek out a solution that elevated the speed, accuracy and efficiency of our packaging operations, while maintaining the high standards of service our customers expect.

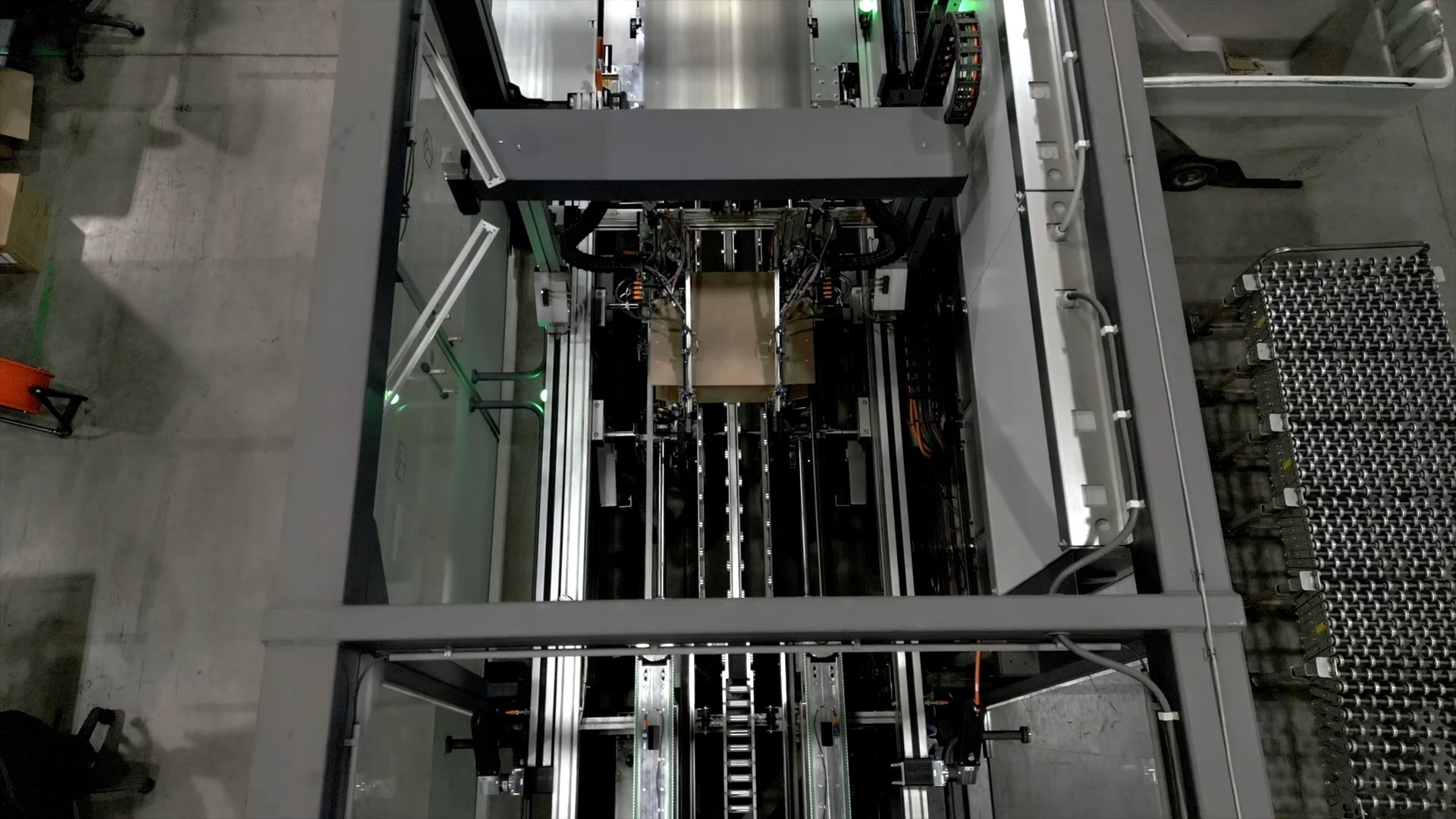

Our solution: right-size packaging automation

To meet these goals, Metro Supply Chain implemented an automated, right-size packaging solution powered by Packsize. The CVP Impack system measures, constructs, tapes, weighs and labels each order in a custom-fit box, eliminating excess materials and reducing waste. The user-friendly system is intuitive and easy to troubleshoot, allowing our team to stay agile.

Achieving our sustainability goals

By ensuring each package is precisely tailored to its contents, right-sized packaging maximizes the number of boxes that can be loaded onto each truck. This not only reduces outbound transportation costs and reduces dimensional weight charges but also minimizes packaging waste and lowers the total number of trucks required on the road. Smaller packages enable carriers to pack more outbound packages in the same available capacity and thereby reduce the average number of kilometers driven (and CO2 produced) per package. These enhancements directly contribute to our sustainability objectives and empower our customers to achieve theirs, fostering more environmentally responsible supply chain practices.

The results

The impact of moving from manual to automated packaging was immediate:

- Up to 2.5X increase in productivity

-

12% savings in linear feet per order

The system gives us the flexibility to scale during high-volume periods without adding strain to our workforce.

Looking forward

By automating our packaging process, we’ve not only boosted productivity but also enhanced our ability to serve customers efficiently and responsibly. This initiative is a prime example of how Metro Supply Chain is leveraging smart automation to drive performance, reduce environmental impact, and stay ahead of the curve in a rapidly evolving logistics landscape.

Related Posts

Health & wellness trends: A 3PL fulfillment guide

Transportation route optimization: smarter logistics, happier customers

How to optimize packaging operations with smart automations

Archived Posts

- september 2024

- january 2024

- february 2024

- march 2024

- may 2024